The portal of chemical risk

Choose the information that best suits your needs by selecting the categories of items from the lists below

Sugar industry: chemical exposure in sugar production

Following a crisis period between 2017 and 2020 due to a change in regulations, the European sugar market is currently experiencing significant growth of almost 50%. As a result, both the production and consumption of sugar are increasing. Sugar is a foodstuff used by individuals as well as by industries for production purposes. The latter represent a large part of the sugar industry's customer portfolio.

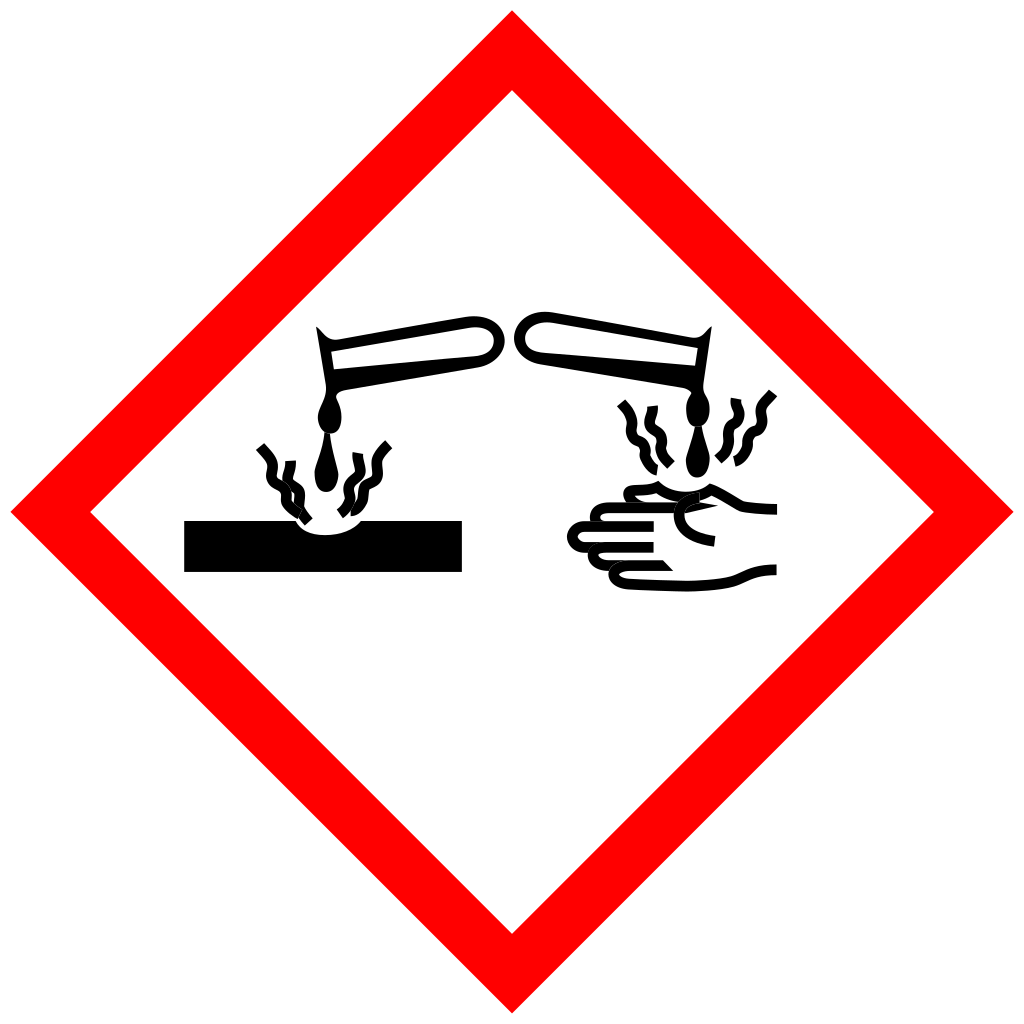

Lime : Chemical risk and Prevention

Exposure to chemical risks in the meat industry

Chemical risks in pharmaceutical industry

Pharmaceutical manufacturing is a complex process that involves the use of a wide range of chemicals, including solvents, reagents, and active ingredients. While these chemicals are essential for producing life-saving medications, they can also pose significant risks to workers if proper safety measures are not in place.

Lithium-ion batteries: why and when do they pose a risk of chemical exposure for people?

In recent years, there has been an increase in the use of motorised personal mobility devices (MPMDs) equipped with a non-combustion engine such as scooters, bicycles, unicycles, hoverboards and similar devices. Like more and more electric vehicles, most MPMDs contain lithium-ion batteries, which are appreciated for their excellent longevity and energy storage efficiency.

Chemical risk in wastewater treatment?

Chemical risks in detergents production

Chemical risks in petrochemical industry

The secrets of solvation

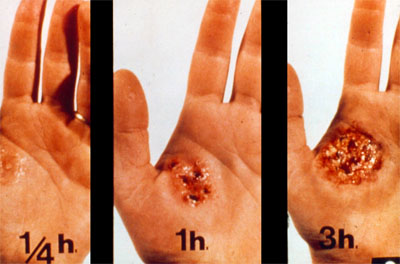

The danger of hydrofluoric acid (HF)

Hydrofluoric acid is a key chemical in many industries, particularly as a surface treatment agent (glass, metals, ceramics, etc.) or as a reaction additive. It is used in many fields of activity, from the production of photovoltaic cells to industrial maintenance in the food industry. Despite the dangers associated with its use, there are few or no substitute products or techniques. This is why its production is growing along with its global demand.

Laboratory – Avoid tissue injuries

The Occupational Health Nurse and risk assessment

Occupational Health Nurse (OHN) and chemicals

Personal nurse experience in safety data sheet’s decryption

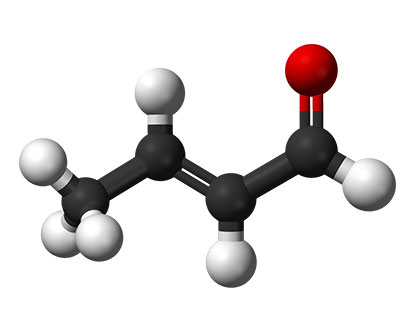

Crotonaldehyde – Focus on specific chemicals of interest

Cancer treatment and chemical hazards

Picric acid: Understanding specific chemicals hazard

European Standard EN 15154 – Safety showers

CE Marking and classification of medical devices

Pictographs in the workplace

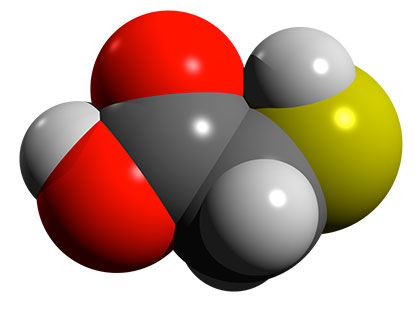

Thioglycolic acid :Understanding the risk of specific chemicals of interest

Chemical risk at home: Hydro soluble unit-dose laundry pods

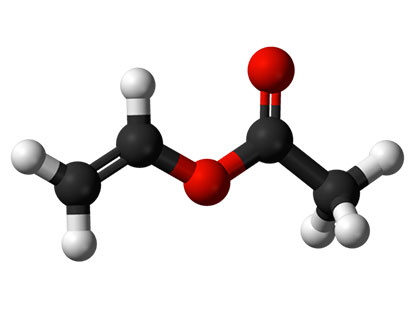

Vinyl acetate: Understanding the risk of specific chemicals of interest

Occupational doctor: What to do on learning through an employee or the director that new chemical products are being used?

Training of occupational health professionals

Are we prepared?

Carcinogens: Different classifications

Nitric acid, a danger lurking

Laboratory – Control chemical exposures

Chemical risks in chemical waste treatment

Chemical risks in semiconductors industry?

Organization of SAMU in Brazil

Chemical risks in mining industry?

Chemical risks in automotive industry

Chemical risks in emergency departments

Chemical risk in industrial subcontracting for the maintenance

Chemical risk in food industry

The food industry produces both finished products for consumption and intermediate products for further processing. It is diverse compared to many other industrial sectors. This diversity can be seen in terms of size and nature of the companies as well as the wide range of raw materials, products and processes. The food industry is subject to very diverse local economic, social and environmental conditions, and varying national legislations.

Chemical risk in paper industry?

The interest of the paper industry market is first of all linked to the complex process required by the production of paper. Two distinct manufacturing operations can be set-up according to the quality of paper needed: mechanical process (mechanical pastes for newsprints and magazines) or chemical process (chemical pastes for writing, impression or packing: sulphite pastes and sulphate pastes or kraft) during which the wood fibres are insulated with chemicals such as bisulfites or sulphates.